Best Dock Materials: Comparing AccuDock to Competitors Materials

Choosing the right dock materials is one of the biggest decisions you will make when planning a dock. The materials you choose affect how long your dock lasts, how much work it needs over time, and how well it performs in changing water conditions. Whether you are a homeowner, marina operator, or managing a public waterfront, the right dock materials make a real difference.

With so many dock material options available today, it can feel overwhelming to know where to start. Wood, composite, PVC, and aluminum are the most common choices, and each one has strengths and drawbacks. This guide breaks down each option in simple terms so you can decide what works best for your dock, your location, and your long term plans.

Why Dock Materials Matter

Dock materials affect a lot more than the look of your dock. They shape how safe it feels under your feet, how well it handles harsh weather, and how many repairs you will deal with over the years. Picking the right dock materials can mean years of smooth use. Picking the wrong ones can mean boards that warp, surfaces that get slick, hardware that loosens, and costs that show up again and again.

Many of these issues are covered in more detail in this guide to dock maintenance tips.

A dock is not like a normal deck in a backyard. It sits over water, gets hit with sun all day, and deals with moisture, waves, and changing water levels. Because of that, dock materials have to handle more stress than most outdoor building materials.

The Biggest Reason Dock Materials Matter: Water and Weather Never Stop

A dock is exposed every single day. Even if you only use it on weekends, the environment still works on it 24/7.

Here is what your dock is up against:

- Water exposure: splashing, spray, rain, humidity, and sometimes standing water

- Sun exposure: UV rays that break down surfaces and fade color over time

- Temperature changes: hot days, cool nights, seasonal swings, and freezing thaw cycles in some areas

- Wind and waves: movement, vibration, and impact forces that stress connections

- Storm conditions: debris, higher water levels, stronger current, and sudden impacts

That is why choosing dock materials is not just a design choice. It is a performance and safety decision.

Planning for storms and water movement is discussed further in this extreme weather preparation guide.

How the Wrong Dock Materials Can Create Problems

A lot of dock problems are not caused by bad installation. They happen because the materials do not match the environment. Over time, the dock starts to show signs that it is struggling.

Common issues you may see with the wrong dock materials include:

- Soft spots, rot, or splintering

- Loose bolts and shifting sections

- Warping boards or uneven walking surfaces

- Algae buildup that makes the surface slippery

- Corrosion on metal parts near saltwater

- Higher maintenance costs than you expected

Even small issues can become expensive if they are ignored, especially when water is involved.

If your dock is near the ocean, it helps to understand how storm surge protection and material choice work together.

Dock Materials and Safety: What Really Matters

Safety is one of the biggest reasons dock materials matter. Most people do not think about dock safety until someone slips, a board breaks, or a dock section feels unstable.

Dock materials directly affect safety in several ways:

- Traction underfoot: Some surfaces get slick when wet, especially if algae builds up.

- Splintering and cracking: Wood can splinter. Some composites can crack. These issues can cause cuts or trips.

- Heat on sunny days: Dark surfaces can get hot fast, especially in summer.

- Structural strength: Some materials handle heavier loads better, like equipment, coolers, or groups of people.

- Stability: On floating docks, the weight of the decking and frame changes how steady the platform feels.

Safety needs to be a top priority when selecting dock materials.

Choosing the right materials goes hand in hand with having the proper dock safety equipment in place.

Durability: Not All Dock Materials Age the Same Way

Durability is not only about how long a material can last. It is also about how it breaks down over time.

Some dock materials fail gradually. Others fail suddenly. That matters because gradual wear gives you warning signs, while sudden failure can become a safety risk.

Here is how durability usually shows up across common dock material options:

- Wood: Can look fine until rot starts inside, especially in damp areas.

- Composite: Often holds up well but can fade or warp depending on quality and heat.

- PVC: Strong resistance to water damage and insects, often stays consistent for years.

- Aluminum: Extremely durable and strong, especially for framing, with excellent performance in demanding environments.

For long term value, durability is a major part of the decision.

For long term performance, it also helps to understand how floating docks work and how materials interact with movement and load.

Maintenance Costs: The Part People Forget to Plan For

Many dock owners focus on the upfront price of dock materials. That makes sense, but it is only part of the real cost.

Maintenance can add up fast when you include:

- Cleaning and algae removal

- Sealing, staining, or painting

- Replacing boards or fasteners

- Fixing loose connections

- Repairing damaged sections after storms

Wood tends to require the most ongoing work. PVC and aluminum generally require less, which can save a lot of time and money over the life of the dock.

A Simple Way to Think About Costs

Instead of only looking at the purchase price, look at the total ownership cost:

- Upfront material cost

- Installation and hardware cost

- Annual cleaning and upkeep cost

- Repairs over time

- Replacement timelines

A dock material option that costs more up front can still be the better deal if it lasts longer and needs less upkeep.

Why “How You Will Use the Dock” Changes Everything

Before choosing dock materials, think about your day to day use. A dock built for occasional family use is very different from a dock built for heavy marina traffic or public access.

Here are a few examples:

- Residential docks: Often focus on comfort, look, and easy upkeep.

- Marinas: Need durability, traction, and strong framing to handle constant traffic.

- Rowing and kayaking docks: Need stable platforms, safe surfaces, and designs that support launching.

- Government and commercial docks: Often require higher load capacity, long lifespan, and ADA friendly access.

The more demanding the use, the more you will benefit from dock materials designed for long term performance.

Water Type Matters: Freshwater vs Saltwater

Not all dock materials handle every type of water the same way.

Freshwater Considerations

Freshwater docks still deal with moisture, algae, and sun exposure. In colder areas, ice movement can add stress too.

Key concerns include:

- Rot and moisture absorption

- Algae buildup and slipperiness

- Seasonal temperature swings

Saltwater Considerations

Saltwater is tougher on docks. Salt speeds up corrosion and can wear down parts faster.

Key concerns include:

- Corrosion on metal fasteners and hardware

- Faster breakdown of certain materials

- Higher maintenance needs if materials are not saltwater friendly

If your dock will sit in brackish water or full saltwater, it is especially important to select dock materials that resist corrosion and water damage.

Dock Materials and Floating Dock Stability

Floating docks depend on balance. The materials used in the frame and decking affect how stable the dock feels when people walk across it.

Dock materials can change stability because of:

- Weight: Heavier decking can make the dock sit lower in the water.

- Flex: Some materials flex more, which can feel bouncy underfoot.

- Movement at connections: The frame and hardware need to stay tight during waves and wakes.

This is one reason many modern modular floating docks use durable, lightweight materials that keep the dock steady and predictable. If your dock will sit near the coast or in brackish water, aluminum framing and PVC decking are often preferred, especially for floating docks in Florida.

Quick Checklist: Choosing Dock Material Options That Make Sense

When you are narrowing down dock material options, ask yourself these questions:

- Who will use the dock most often?

- Will people walk barefoot on it?

- Will it support equipment, carts, or heavy loads?

- Is it freshwater, saltwater, or brackish water?

- Do you want low maintenance or are you okay doing regular upkeep?

- Is the dock exposed to big wakes, current, or storms?

- Do you need the dock to expand or change later?

The answers help point you toward dock materials that will hold up and fit your lifestyle or project needs.

Questions Readers Usually Have About Dock Materials

How do I know if my dock materials are not holding up?

Look for signs like splintering, soft spots, loose hardware, warping, or slick surfaces. If you are making frequent repairs or the dock feels less stable than before, the dock materials may not be the right fit for the environment.

Are low maintenance dock materials worth it?

Often, yes. Low maintenance dock materials like PVC and aluminum can cost more up front, but they usually save money over time through fewer repairs and less upkeep. They also save time, which matters to most dock owners.

Do dock materials affect how safe the dock is for kids and guests?

Yes. Dock materials impact traction, splinter risk, surface temperature, and stability. If safety is a priority, focus on dock material options that resist slipping, do not splinter, and stay stable in changing water conditions.

Can dock materials help a dock last longer in harsh climates?

Absolutely. Climate plays a big role in how docks age. UV exposure, heat, storms, ice, and saltwater all put stress on materials. Choosing dock materials designed for those conditions can extend dock life and cut down on repairs.

What is the biggest mistake people make when picking dock material options?

A common mistake is choosing based only on upfront price or appearance. The better approach is matching dock materials to water type, climate, traffic level, and long term maintenance expectations.

Dock materials matter because your dock lives in a tough environment. Water, sun, weather, and daily use all add up over time. The right dock materials improve safety, reduce maintenance headaches, and help your dock stay solid for years. When you understand how water type, climate, foot traffic, and load needs affect dock performance, it becomes much easier to choose dock material options that truly fit your project.

This is why many modern systems combine aluminum framing with PVC decking, a setup commonly used in floating dock systems for lakes and waterfronts.

Overview of Common Dock Material Options

Most docks today are built using one or a combination of these materials:

- Wood

- Composite

- PVC

- Aluminum

Each of these dock materials serves a purpose. The best choice depends on how and where the dock will be used.

Wood Dock Materials

Wood has been used for docks for many years. Many people like the natural look and familiar feel of wood, especially for residential docks.

Pros of Wood Dock Materials

Wood docks are often chosen for these reasons:

- Natural appearance that blends into waterfront settings

- Lower upfront cost compared to some materials

- Easy to cut, adjust, and customize during installation

- Widely available in most areas

For homeowners who like a traditional look and are comfortable with upkeep, wood can be appealing.

Cons of Wood Dock Materials

Wood also comes with some clear downsides:

- Can rot, splinter, or attract insects

- Requires regular sealing or staining

- Shorter lifespan, especially in wet or saltwater areas

- Can become slippery as algae and moisture build up

Over time, maintenance costs and repairs often make wood more expensive than it first appears.

Composite Dock Materials

Composite decking is a popular alternative to wood. It is made from a mix of wood fibers and plastic, designed to last longer than natural lumber.

Benefits of Composite Dock Materials

Composite dock materials offer several advantages:

- Better resistance to moisture and rot than wood

- Less splintering, which is safer for bare feet

- More consistent look over time

- Less frequent sealing or staining

Many dock owners choose composite because it offers a balance between appearance and durability.

Drawbacks of Composite Dock Materials

There are a few things to keep in mind:

- Higher upfront cost than wood

- Can get warm in direct sunlight

- Heavier than PVC decking

- Wood fibers can still break down over time

Composite works well for residential docks and light commercial use where appearance matters.

PVC Dock Materials

PVC dock materials are fully synthetic and designed for long term performance with very little maintenance. These materials are commonly used in modern floating dock systems.

Why PVC Dock Materials Are Popular

PVC docks stand out for their durability and ease of care:

- Highly resistant to water, rot, and insects

- Perform well in freshwater and saltwater

- Lightweight, which supports floating dock performance

- Smooth and comfortable underfoot

- Very low maintenance needs

For dock owners who want fewer repairs and less upkeep, PVC is often a smart choice.

Things to Consider With PVC Dock Materials

PVC is not perfect for every situation:

- Higher upfront cost than wood

- Modern look may not suit every setting

- Quality depends on the manufacturer

When paired with a modular floating dock system, PVC dock materials often provide strong long term value.

Aluminum Dock Materials

Aluminum is widely used for dock frames and decking in commercial, marina, and government projects. It is known for strength and long lifespan.

Advantages of Aluminum Dock Materials

Aluminum docks offer several key benefits:

- Extremely durable and corrosion resistant

- Long lifespan with minimal structural maintenance

- Strong enough for heavy loads and frequent use

- Performs well in harsh climates

- Lightweight compared to steel

These qualities make aluminum ideal for high traffic docks and work platforms.

Downsides of Aluminum Dock Materials

There are a few drawbacks to keep in mind:

- Higher initial cost

- More industrial appearance unless paired with decking

- Can feel hot in direct sunlight

For projects where strength and longevity matter most, aluminum dock materials are often worth the investment.

Dock Material Options Compared

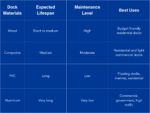

Looking at dock material options side by side helps make the differences clearer.

This comparison shows why many modern floating dock systems use PVC decking with aluminum frames.

How Dock Materials Affect Floating Docks

Floating docks move up and down with changing water levels. Because of this, dock materials must handle constant exposure to water and shifting loads.

Heavier materials or materials that absorb water can affect stability over time. Dock materials like PVC and aluminum work especially well for floating docks because they are lightweight, water resistant, and strong.

These materials also support modular designs, making it easier to expand or adjust the dock in the future.

Choosing the Right Dock Materials for Your Needs

To narrow down dock material options, ask a few practical questions:

- How often will the dock be used

- Will it support people only or equipment too

- Is the dock in freshwater or saltwater

- How much maintenance are you comfortable with

- Do you need ADA access or modular features

Your answers help point you toward the right dock materials.

For example:

- Homeowners often value comfort and appearance

- Marinas focus on durability and safety

- Government projects prioritize long term performance and compliance

Frequently Asked Questions About Dock Materials

What are the best dock materials for floating docks?

The best dock materials for floating docks are usually PVC decking paired with aluminum frames. These materials resist water damage, require little upkeep, and support modular designs.

How long do different dock materials last?

Lifespan depends on the material and environment. Wood may last 10 to 15 years with regular maintenance. Composite often lasts around 20 years. PVC and aluminum dock materials can last several decades.

Are PVC dock material options safe for bare feet?

Yes. PVC dock materials are smooth, non splintering, and slip resistant, making them comfortable and safe for bare feet.

Do aluminum dock materials rust?

Aluminum does not rust like steel. Marine grade aluminum resists corrosion, even in saltwater, which makes it a strong choice for coastal docks.

How do dock materials affect maintenance costs?

Maintenance costs vary widely. Wood requires frequent care. Composite needs occasional upkeep. PVC and aluminum dock materials have the lowest long term maintenance needs.

Can dock material options be combined?

Yes. Many modern docks use aluminum frames with PVC decking to combine strength, durability, and comfort.

Making the Right Choice for Dock Materials

Choosing the right dock materials is about planning for the long term. While upfront cost matters, durability, safety, and maintenance play an even bigger role over time. With so many dock material options available, understanding how wood, composite, PVC, and aluminum compare helps you make a confident decision.

For floating docks that need strength, flexibility, and low maintenance, materials like PVC decking and aluminum framing often deliver the best overall performance. These dock materials support modular designs, handle tough environments, and provide dependable use year after year.

If you are planning a new dock or upgrading an existing one, contact AccuDock for more information. Our team can help you design a floating dock system that fits your needs.

AccuDock is a global leader in the design and manufacturing of Floating Docks

CALL 954.785.7557 OR EMAIL [email protected] FOR MORE INFORMATION